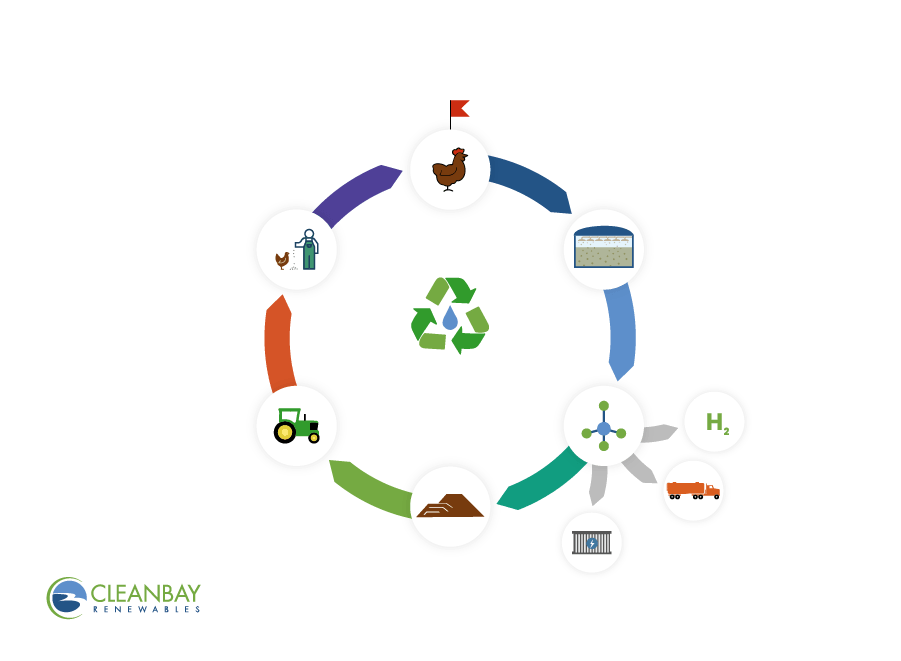

Carbon Reduction within the Circular Ecosystem

More than 14 million tons of chicken litter is produced each year in the United States. It’s a significant challenge in need of a sustainable solution. CleanBay Renewables believes our process to turn this waste into renewable natural gas and natural fertilizer is part of the answer.

Step One

Enclosed tractor trailers with specialized walking floors deliver chicken litter directly into our airtight systems, all within minutes of arriving onsite.

Step Two

The chicken litter mixes with water in an oxygen-free digester tank at a temperature of 98 degrees Fahrenheit and remains there for roughly 25 days. During this process, the materials begin to break down creating two usable products – a renewable natural gas and a natural fertilizer.

Step Three

This renewable natural gas (RNG) is made of methane, the same material commonly used to heat homes and cook. The gas rises to the top of the tank while the solid materials, called digestate, sit just below.

Step Four

The gas is pulled from the tank and cleaned, upgrading it to pipeline quality standards. It can then be collected and transferred to the natural gas distribution system to be used for electricity generation or as a replacement vehicle fuel.

Step Five

The remaining solid material is further refined using mechanical and chemical processes to create a natural fertilizer product. This process helps significantly remove and stabilize elements like phosphorous and nitrogen, which in some regions easily wash away, polluting the water supply.

Step Six

The controlled-release biostimulant fertilizer is then available for local farmers and their suppliers to use as a natural additive for their fields. This product is also able to satisfy the growing demand for organic products in other high-value market segments such as open field fruit & vegetables, professional turf & ornamentals, home lawn care, and hobby gardening.

Step Seven

The water used in this process is then fully recycled into the plant.